Date:Jul. 16, 2025

Hours:112

Brief Description:

After flying the RV-10 about 500 hours it became apparent that just a few more gallons of fuel would be nice to have. The cheapest speed mod is more fuel capacity! I looked at the “then available” solutions of wing tip mounted tanks as well as tubular tanks that slid into the wing rib lightening holes. I did not like the complexity of extra fuel lines, pumps, etc. nor the engineering pedigree of those solutions. While I had also seen folks double up on the stock Rv-10 tanks by installing a second pair of them and tanker around (120) gallons of fuel, I felt that was a bit outside my comfort zone as I was unable to find any engineering data that supported the modification.

Then came along the Sky Designs ER tanks! As far as complexity, the larger Sky Designs tanks simply replace the original tanks and two bays of wing ribs. No additional pumps, fuel lines, etc. The ER tanks were designed by Ken Krueger who while at his time working for Vans designed the RV-10 wing. Who better to trust with a modification to the original design than the person who designed the original design? With that in mind I was sold on the idea and ordered one of the first (50) sets of ER tanks from Ken. I flew the Skyscraper out to Vans in Aurora from Orlando and picked up the remaining bits and pieces from Vans. Then struck the LCP (Laser Cut Parts) debacle. I promptly put a halt on all aircraft building (RV-10 ER tanks and RV-8 QB build) until the dust settled. Despite Vans guidance that LCP fuel tank ribs are OK, and while all the fuel tank dimples and rivets get pro sealed (this would mitigate any cracking caused by LCP parts) I decided it best to replace the LCP parts with traditional punched parts. Ken was gracious enough to swap the original LCP skins he sent me for punched skins. What customer service! Vans was kind enough to ring my credit card again and take another order for replacement parts!

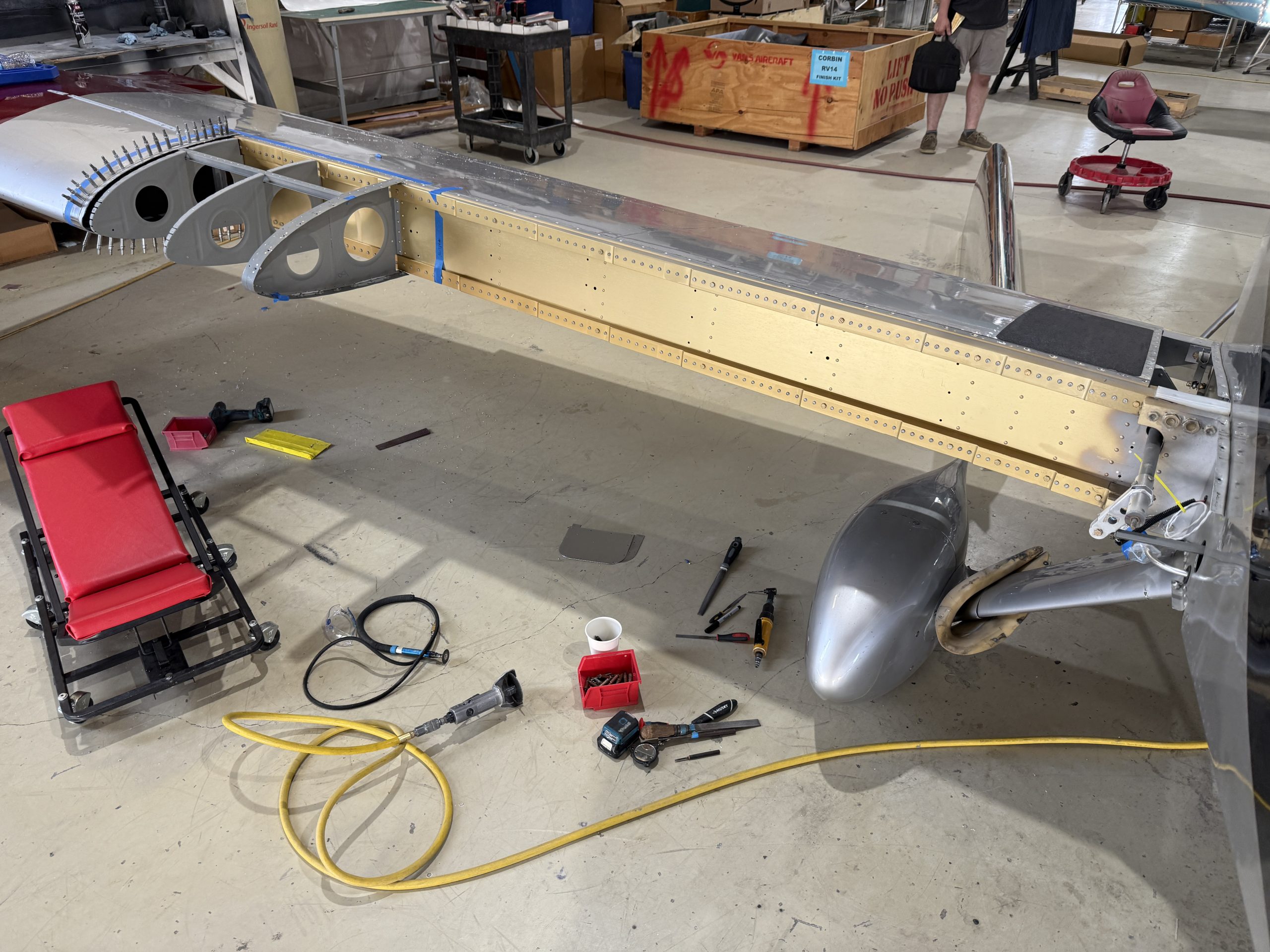

I’ll start off by saying that building these tanks and modifying the wings to accept them is no trivial endeavor. I decided it best to peel the band-aid off as fast as I could to keep the airplane down for the shortest period of time and get some hired help to complete the task. Income Synergy Air South. Having previously been to Newnan, Georgia to check them out before I bought N7ZK I had an idea of how they operate. I’ve run across many companies in my life and very few in operate with the integrity and grit of Synergy. The folks in their shop work hard ALL DAY at a very rapid pace. They are punctual, professional, and knowledgeable. If you find yourself looking for an accelerator to get things going faster, money with them is well spent. Building the tanks in that environment took us (80) man hours. One full week with two people. Modifying the wings and installing the tanks took us (112) man hours. That is seven days with two people. Total project = 192 man hours excluding the time I spent running new wires from the behind the panel to the wing roots. The (4) new Cies senders needed an additional wire from the panel as they have a ground, power, and a signal wire.

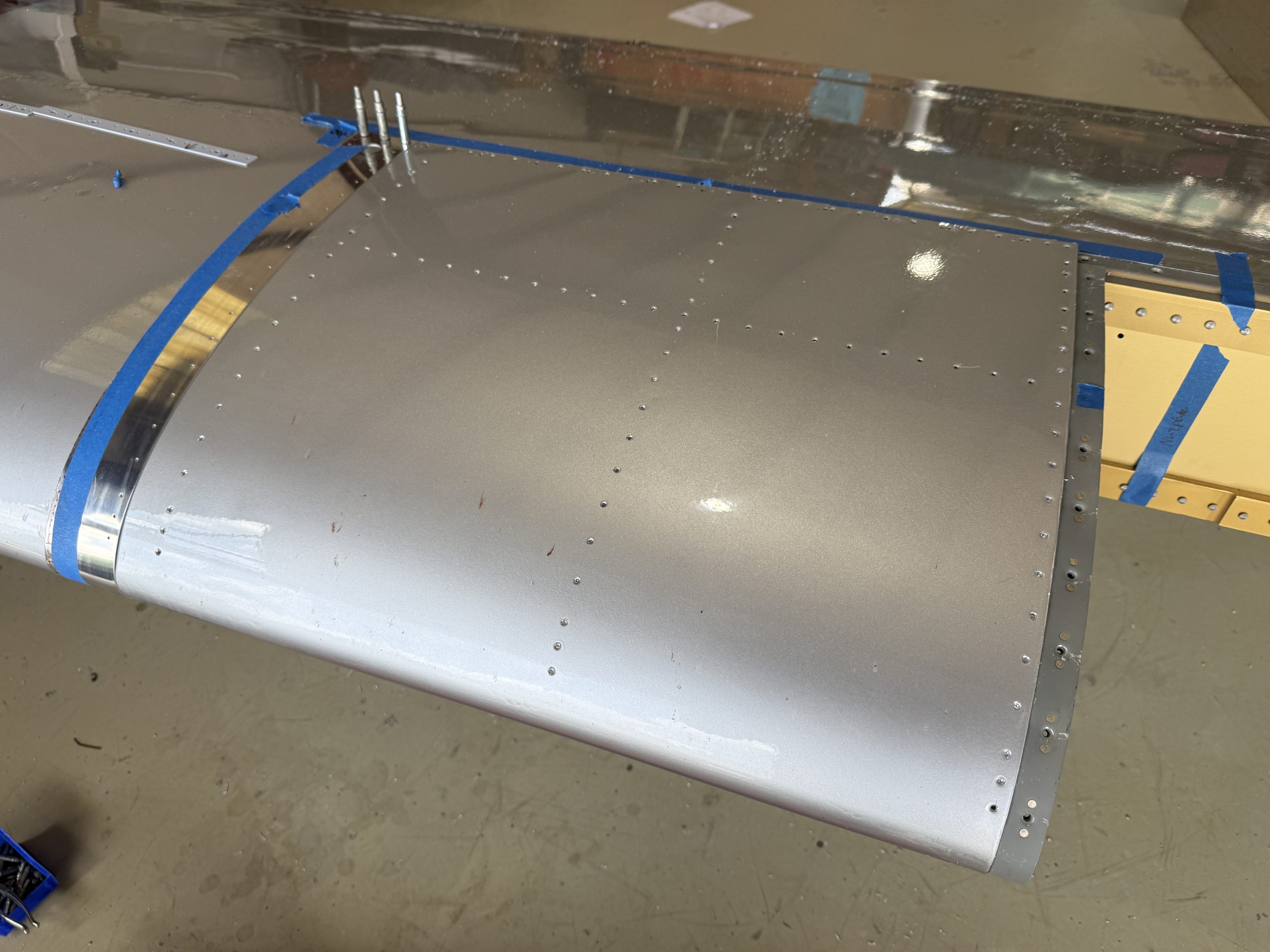

Pre wing skin cut. The shiny cut guide template is installed and wing skin rivets have been drilled out.

Post wing skin cut. The inboard rib with nut plates gets re-used. The other two ribs leave.

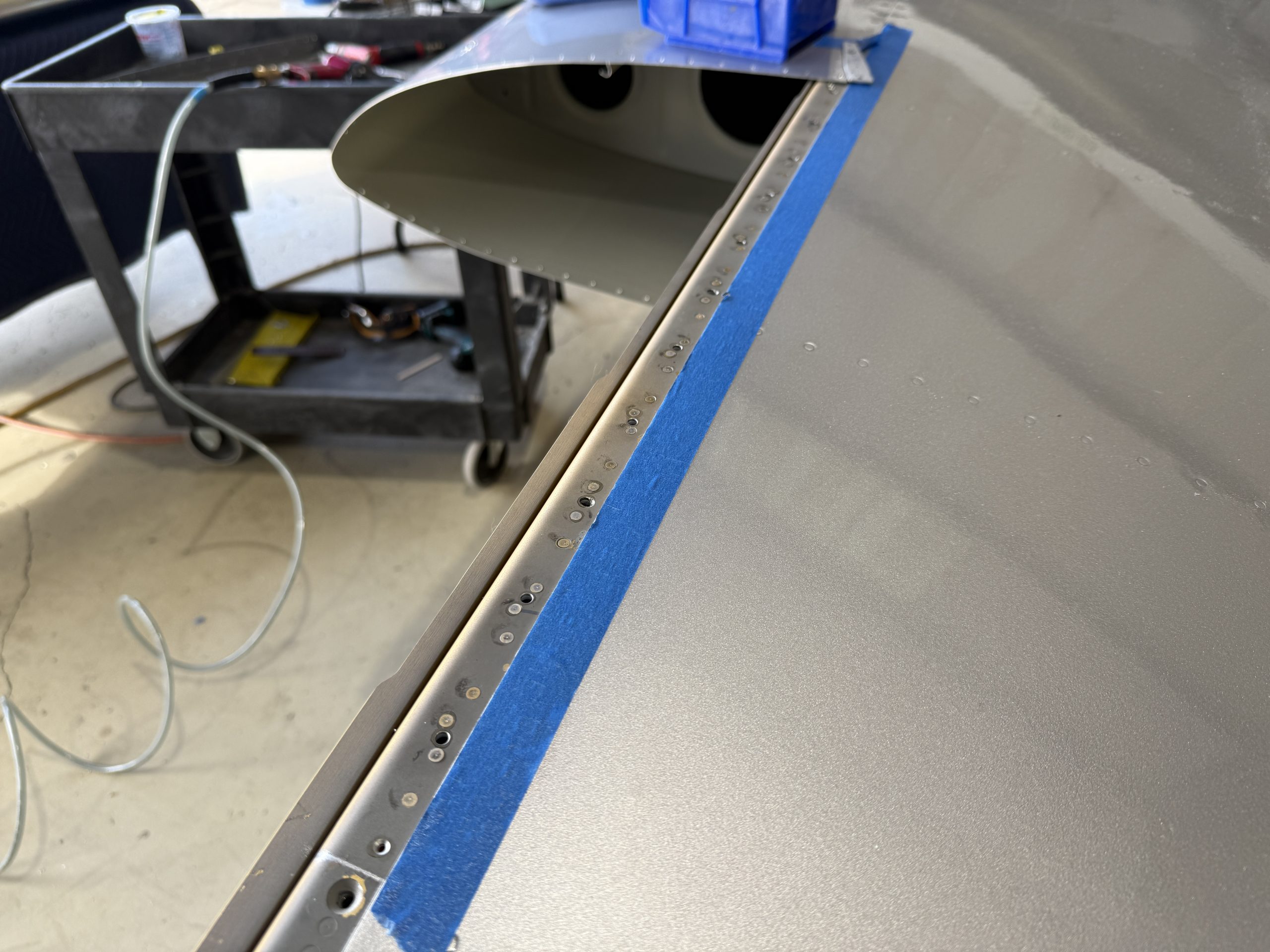

Post wing skin cut and edge filed to finished shape.

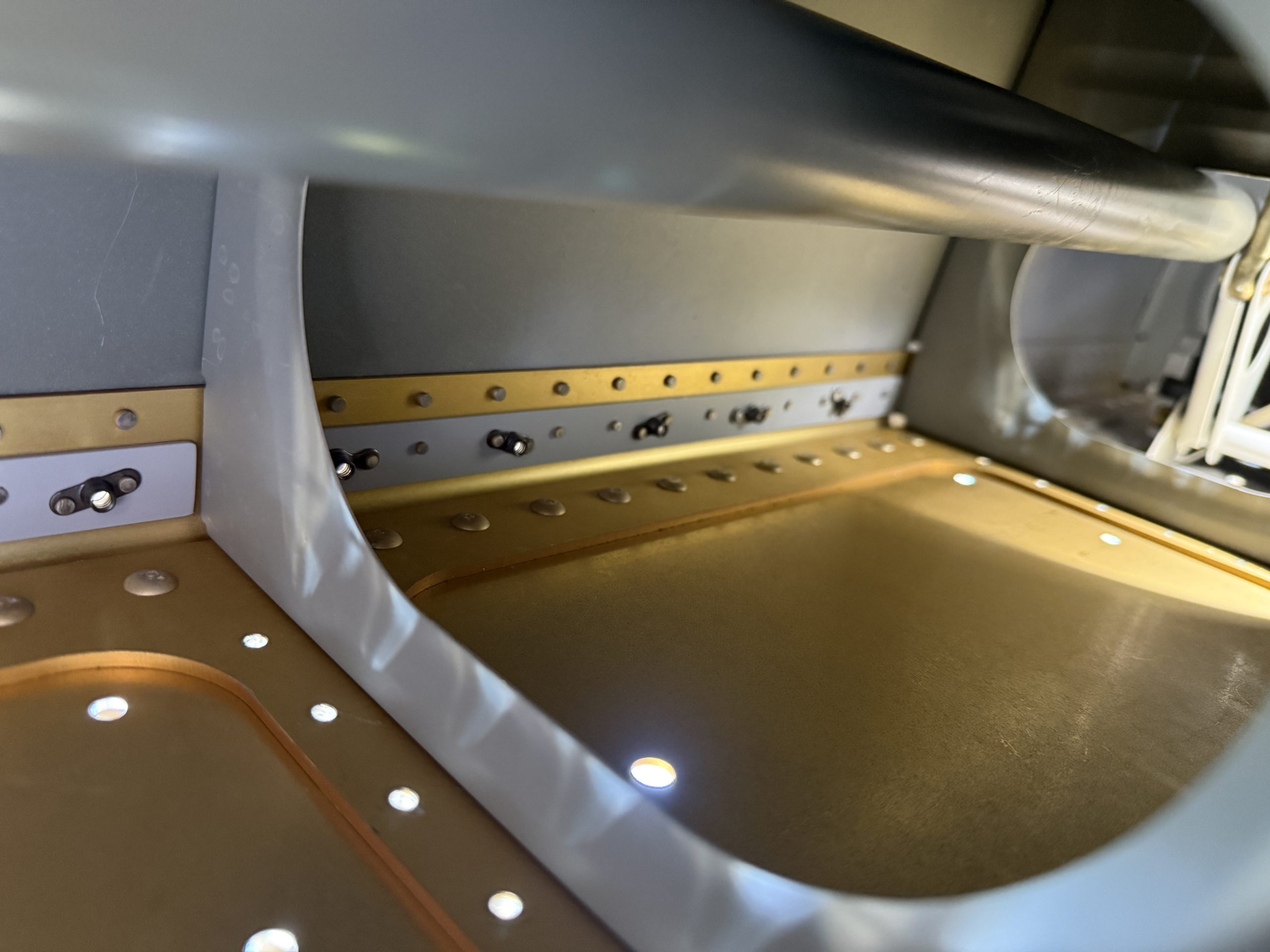

The tedious spar doublers and nut plates. Don’t strip one out!

More spar doublers and nut plates.

The unpainted ER tanks each weigh 2 pounds more than the painted stock tanks/skins/ribs/stiffeners they replace.

Stock tanks and skins loaded in the rental car before heading from Newnan to Orlando.

Dan graciously giving me a ride to Aircraft Spruce for some odds and ends while Skyscraper is apart. Thanks Dan!

Loving my M12 Milwaukee.

Outboard Cies sender. You can see the (4) pro sealed rivets for the right tank’s tab (nearest the camera).

Note the extra inspection panel that the modification adds for access to the extra Z brackets in the extra (2) bays.

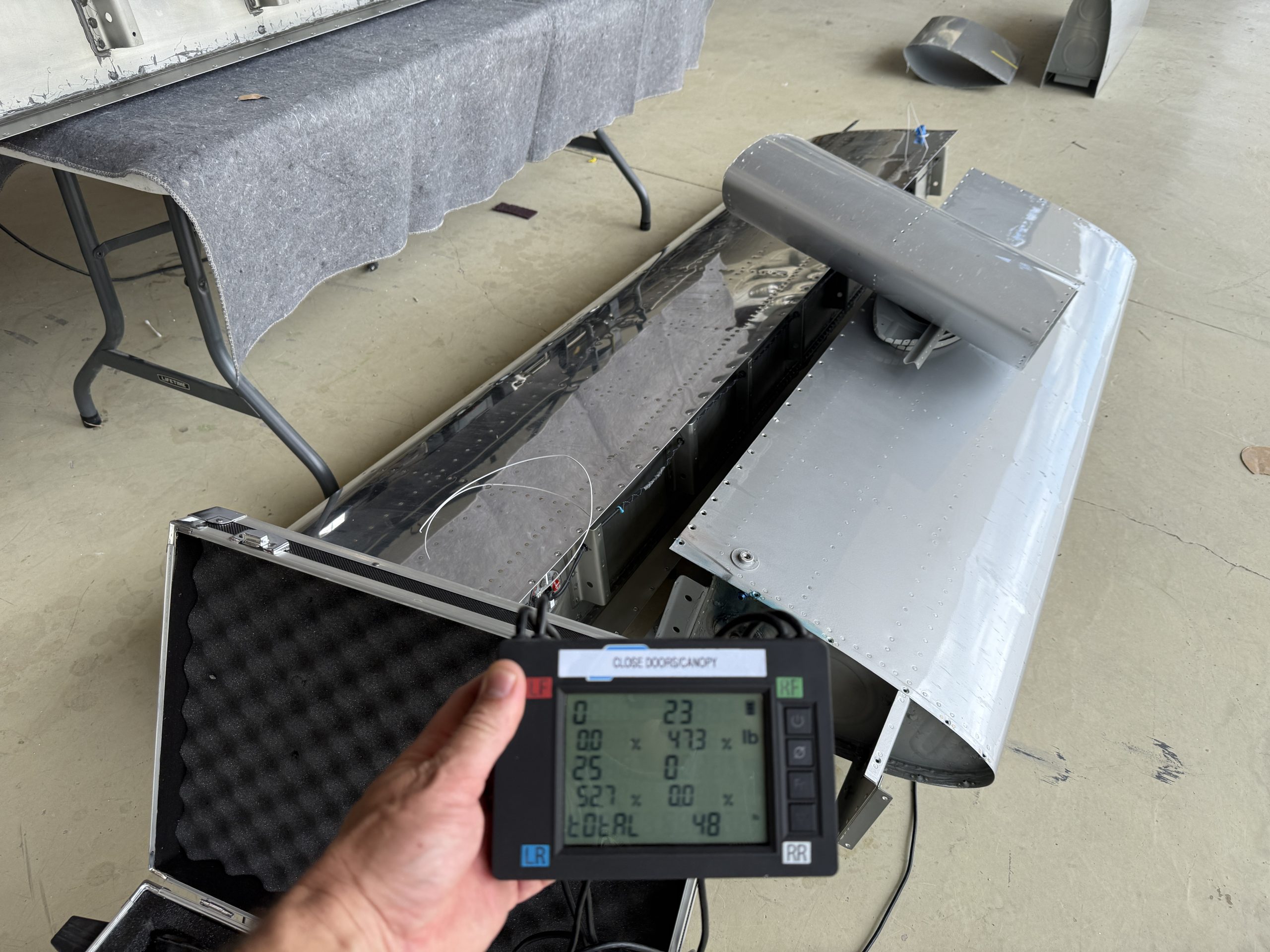

N7ZK put back together waiting for the fuel truck to calibrate the Cies senders.

After filling each tank 5 gallons at a time from the fuel truck I drained it all back out at the root through a filter funnel.

After the flight back to Orlando the approximate 60 gallons of fuel was cold.

N7ZK gives another “first RV Grin”.

Project totals:

Build both ER tanks – (80) man hours

Wing modification and installation of both new tanks – (112) man hours (excludes running new wire from panel to wing roots)

Onboard fuel increased from 60 to 83.