Date:Mar. 12, 2018

Hours:2

Brief Description:Used the new pneumatic sander for the first time to take the fins off the sheared edges.

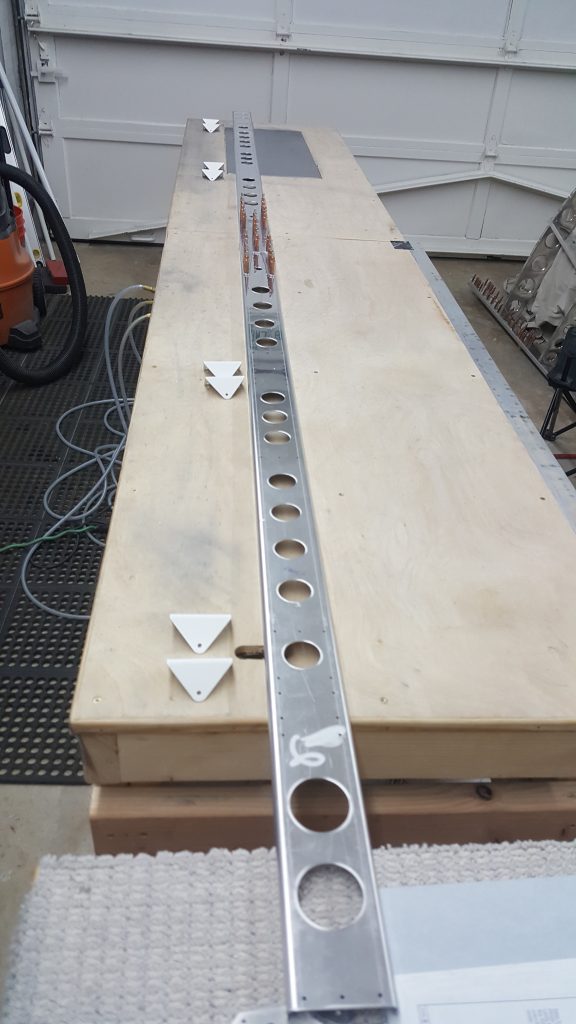

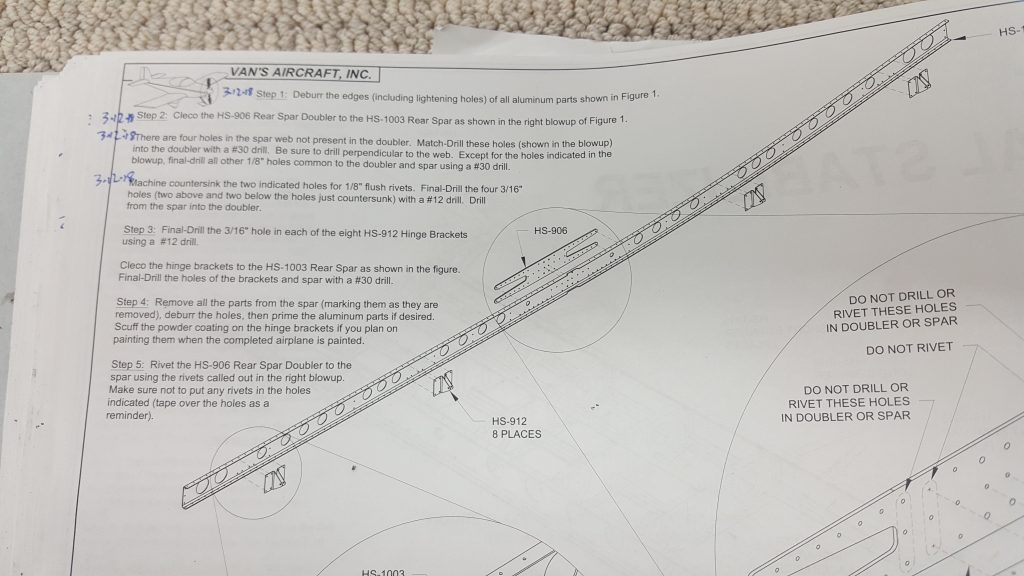

Used the 3/8″ belt sander with 180 grit followed by two passes with a V-blade edge deburring tool, die grinder with 2″ blue scotch brite, then a 1″ 3M EXL wheel to deburr the flanges on the HS-1003 rear spar. The lightening holes were hit with a 1″ 3m 7A wheel then a 3m 1″ EXL wheel and came out very smooth. Drilled the (4) missing holes in the HS-906 doubler, match drilled all the holes per the plans. The DRILL GUIDE worked very well for the #30 holes close to the flange. As a quality control measure I also bought a EGG CUP DRILL STAND SET but the flange was a bit tight so the drill guide came out of the tool box.