Date:Mar. 14, 2018

Hours:0.5

Brief Description:You eat the elephant one bite at a time.

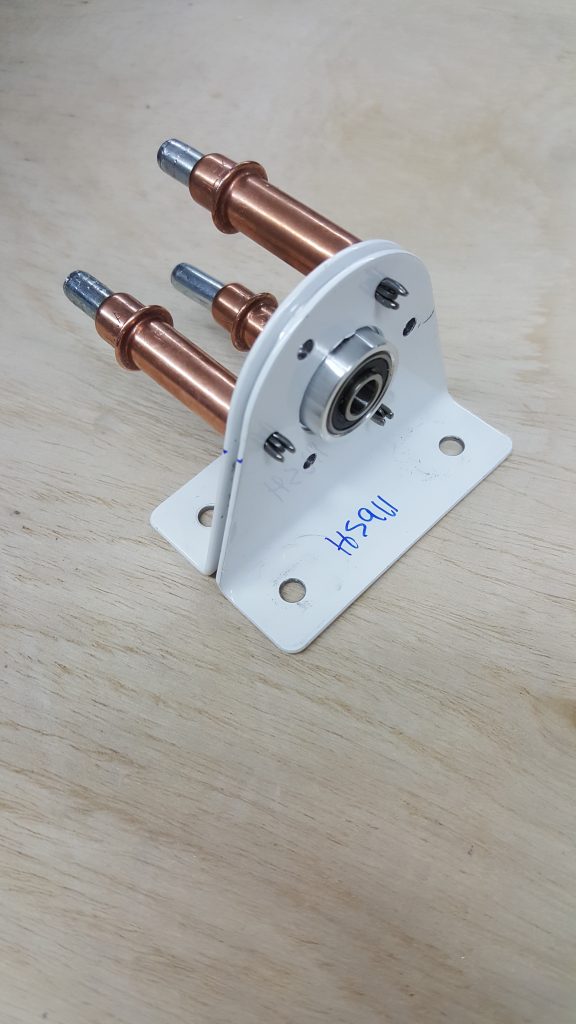

Per the plans used a #30 in the air drill for the 6 holes up top and a #12 in the drill press for the holes in the returns on the bottom (of the picture). Followed this up with the single flute 100 degree deburr tool. While match drilling the 6 holes I clamped the brackets down to a piece of aluminum angle from the kit to keep them in the proper orientation. Marked the bearing with a single slash on it to orient it back in place. This is not enough as it can be flipped side for side and be oriented “backwards” from the match drilled setup. Next time will need to mark differently.